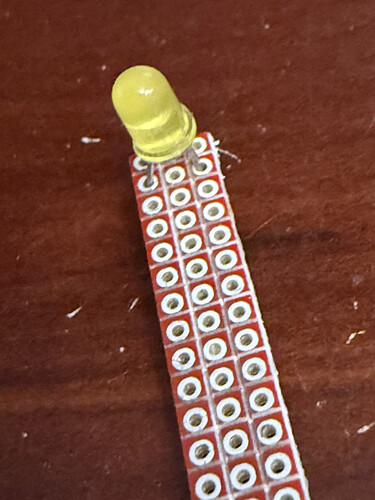

If an LED is mounted outside as shown below and got rained or snowed on, would it be able to withstand it or would it short circuited/damaged? If so, would an acrylic coating be enough to protect it from the weather?

The LED might survive, but if the PCB gets damp (even from condensation when the temperature drops) and power is applied, corrosion will rapidly set in, setting up undesirable conductive paths and eventually, destroy the solder joints and copper on the PCB.

For long term survival outdoors or in damp environments like cold rooms or unheated spaces, finished PCBs are “conformally coated” (think of a layer of nail polish) or potted in silicon compound.

Acrylic (AR) conformal coating would be the minimum you should be thinking off for conformal coating for your application. But for an outside application I would recommend Urethane (UR) conformal coating. Silicone (SR) may be better still; but UR should be sufficient. Between those two; whichever is cheapest.

Some good reading:

A Comprehensive Guide to Silicone, Urethane, and Acrylic Coatings

Conformal Coating Types: Acrylic, Urethane, Silicone and Parylene | Specialty Coating Systems

Sealing the LED leads from ambient conditions is enough to weather-proof a standard LED, but take extreme care with things like conformal coatings! Even a rubber O-ring seal is bad, because the plasticiser can get into the acrylic and migrate to the emitting element and destroy it. I had that happen, and compared to another (unused) LED of same type, bought at same time, the innards of the used LED were visibly discoloured, but it was working last time it had power. The only possible cause was the deteriorated rubber O-ring (it had also damaged the seal of the closest of two silver oxide coin cells, which is why it was an obvious link with proximity to a source of contamination), and I used a silicone O-ring replacement after fitting a working LED and two new coin cells.

Don’t take my word for this, it’s a known failure state for LED’s and once I suspected it, it was not hard to find plenty of confirmation that the problem exists, so take care with ANYTHING that can release volatile hydrocarbons (or plasticisers) at length close to an LED. Keep it well ventilated on either side of any bulkhead used to seal it against weather or contamination, if you want a long healthy life for it.

EDIT:

There is a good acrylic spray by Krylon, called ‘Crystal Clear’, that is excellent for making laser-printed mylar films darker, and protecting them, for PCB prototyping. It may be acceptable for protecting an LED, given that both are acrylic. I’m not suggesting that it is, but it might be worth testing if you have some.

Even with coating, I doubt that the LED and perf board, squints possibly unsoldered, functions 6 months in weather: Temperature, UV, water, freeze/thaw, mildew, animals.