My team purchased the Bourns Absolute Encoder (EAW0J-B24-AE0128L) for a project partially due to the listed running torque (0.5-1.5 N-cm). However, it was incredibly stiff. We expected something akin to a car volume dial and were shocked at how difficult it was to turn. I also noticed no breakaway torque was listed. Is there a different component that would be better suited for the approximate resistance of a car volume dial? Also any explanation why the components ordered were so stiff? Thank you!

They’re usually designed to have a knob placed on the rod after mounting to let it be used more freely…if you’re just using the rod I believe that is the source of your troubles

I recently came to the same conclusion when replacing an encoder on a radio and thought, “This can’t be right.” The extra leverage from even a half inch/12mm knob was substantially greater than I expected and it did loosen up a little over time.

Oh I feel kind of stupid now! Other encoders we’ve used came with the knobs, but this one didn’t. It was still significantly harder to turn than the other ones we’ve used with just the rod, but I’m wondering if we got a low-end running torque on the other and a high-end on this one.

Certainly, some are going to be mechanically tighter that others, even among encoders for which turn torque is a primary design consideration. Like a lot of specs (say water & dust ingress, green coloration of the board dye, detent consistency, shaft knurling depths, 10^8 rotation cycle MTBF), uniformity of the torque probably wasn’t in the top 5 for this particular encoder.

I would expect something as heavily handled in a mass market vehicle as the audio volume knob to get special attention from the fit & feel folks in the design and ergonomics teams. Custom encoders are likely and some might have flywheels or maybe even force feedback.

I know I’m going off-topic here. But if you’re ever looking for a way to fill your spare time, check out Scott Bezek’s SmartKnob: “A brushless gimbal motor is paired with a magnetic encoder to provide closed-loop torque feedback control”. The Demo video is well worth a watch. Enjoy!

Gosh, you’re right, that’s cool. I legitimately wish I had problem needing a knob solution right now.

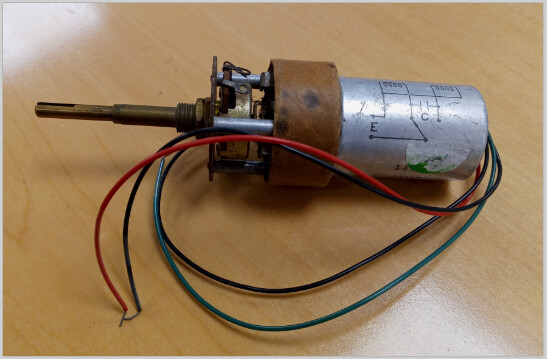

I happen to have this dusty ancestor on my desk right now. It performed a ‘somewhat’ similar function (one of them, anyway), the motor (silver can with wires) could actuate the potentiometer (terminals unpopulated in pic). There’s an additional reduction mech under the cardboard tube but the three brass gears I can see in the gap are very high quality. This must have cost a bundle to produce.