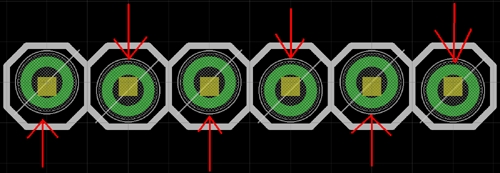

Is there any reason why SparkFun’s Qwiic SHIM isn’t made with slightly staggered pin holes like

I occasionally see people complaining that the SHIM’s pin contacts can be unreliable in its current form since it’s common for full rows of pins to vary in how much they bend toward/away from each other. Meanwhile, this alternating hole placement has proven to be highly effective for avoiding this issue in other ‘solderless’ products since the increased variation in spacing results in each individual pin contributing to maintaining a friction contact.

I’m not an expert on large-scale manufacturing, but this sort of adjustment doesn’t appear to change the cost of production in small-batch PCB orders